AI is transforming factory floors by deploying intelligent machines that automate routine tasks, enhance safety, and improve efficiency. Robots handle quality inspections, predictive maintenance, and material handling, reducing errors and downtime. These advancements also create new roles requiring technical skills, but they can impact job security for blue-collar workers. To stay ahead, you’ll want to explore how workforce training and innovation are shaping manufacturing’s future. Keep going to discover how you can adapt to these changes.

Key Takeaways

- AI-powered robots and cobots assist blue-collar workers by automating routine tasks like welding, material handling, and assembly.

- Intelligent machines improve quality control through real-time defect detection, reducing rework and scrap rates.

- Predictive maintenance AI analyzes sensor data to prevent equipment failures, enhancing safety and reducing downtime.

- AI-driven safety systems monitor hazards, environmental conditions, and worker behavior to prevent accidents on the factory floor.

- Workforce roles are evolving, requiring workers to develop new technical and soft skills to collaborate effectively with intelligent machines.

The Evolving Role of Blue-Collar Workers in Manufacturing

As manufacturing evolves with new technologies, the role of blue-collar workers is changing rapidly. You’re now part of a growing sector that could add 1.5 million jobs by 2025, but there’s a skills gap—around two million positions may go unfilled. Advanced manufacturing areas like CNC machining and automation demand specialized skills, pushing you to learn new techniques and earn certifications. The industry is actively hiring, with nearly half a million job openings in April 2024 alone. To stay competitive, you’ll need to adapt quickly to emerging technologies, including IoT and sensors. While job satisfaction remains a concern, improving work conditions and acquiring advanced skills can boost your stability and career growth in this evolving landscape. Blue-collar workers are increasingly seeking training and education to meet these new demands, highlighting the importance of skill development for future job security. Additionally, embracing technological advancements can help you remain relevant and competitive in a rapidly changing industry. Developing proficiency in digital tools and automation is becoming essential for adapting to modern manufacturing environments. Recognizing the importance of specialized skills can also help you better navigate the shifting landscape and seize new opportunities. Moreover, participating in Hackathons focused on manufacturing innovations can provide practical experience and foster connections with industry experts.

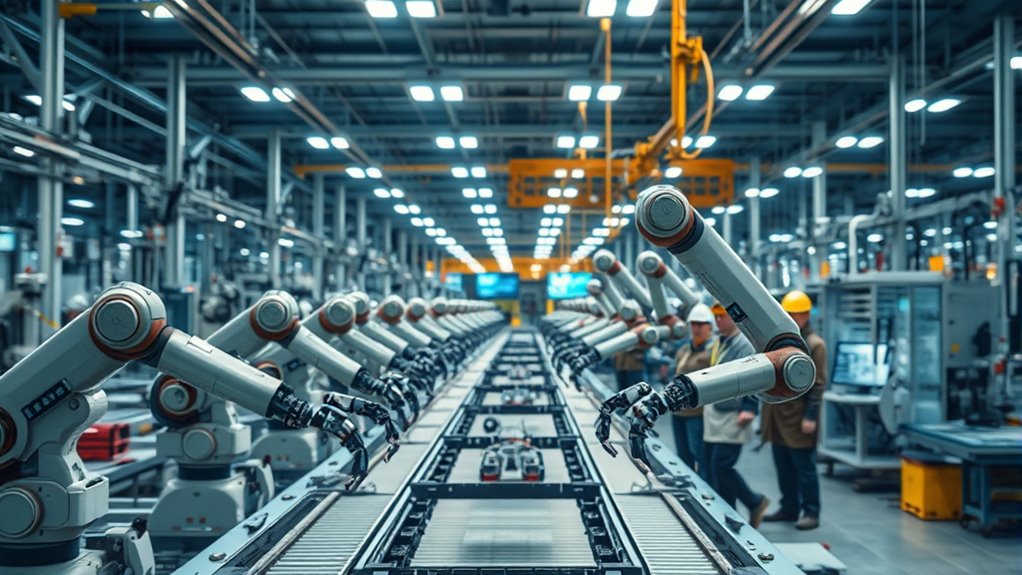

How AI Is Automating Routine Tasks on the Factory Floor

AI is transforming the factory floor by taking over routine tasks like quality inspections, predictive maintenance, and assembly. You’ll see robotic arms and vision systems working together to catch defects and perform repairs before issues escalate. This shift helps streamline operations, reduce errors, and free up workers for more complex responsibilities. AI’s ability to process diverse data types enables real-time analysis and decision-making, further enhancing manufacturing efficiency. Additionally, proper storage and handling of materials on the factory floor contribute to maintaining product quality and safety. Implementing standardized procedures can further optimize workflows and ensure consistent product standards. Furthermore, adopting ergonomic workspaces can improve worker safety and productivity in these automated environments. Incorporating aesthetic wall organization solutions can also help create a more organized and visually appealing workspace, boosting morale and efficiency.

Automated Quality Inspections

Have you ever wondered how factories guarantee their products meet strict quality standards so quickly? Automated Optical Inspection (AOI) powered by AI makes this possible. It detects defects faster and more accurately than manual checks, reaching up to 90% accuracy compared to human inspectors’ 60–90%. AI-driven AOI provides real-time feedback, allowing immediate corrections and reducing bottlenecks, especially in high-speed production. It also eliminates errors caused by fatigue or subjective judgment, ensuring consistent quality across shifts. This automation cuts costs by lowering labor expenses—consider that QC inspectors earn over $89,000 annually in the US—and reduces scrap and rework rates. Furthermore, security considerations are essential when implementing AI systems to protect sensitive manufacturing data. As a result, production lines run smoother, defects decrease, and overall product quality improves markedly, supporting higher customer satisfaction. AI vision has transformed quality assurance processes, enabling quicker defect detection and higher standards across manufacturing sectors, supporting ongoing process optimization and higher quality levels. Additionally, understanding the causes of defects helps in refining AI algorithms for even better accuracy and reliability. Incorporating advanced machine learning techniques can further enhance defect detection capabilities, leading to more reliable and efficient quality control.

Predictive Maintenance Tasks

Automated quality inspections keep defects in check, but maintaining equipment health is equally essential for smooth production. AI-driven predictive maintenance helps you achieve this by analyzing sensor data in real-time to detect early signs of failure. It integrates with sensors to continuously monitor machinery, using machine learning models to forecast potential issues before they happen. This proactive approach reduces unexpected breakdowns, minimizes downtime, and lowers maintenance costs—sometimes by up to 25%. AI also helps you allocate resources more efficiently, prioritizing urgent repairs. Industry leaders like Rolls-Royce and GE have already seen significant savings and reliability improvements. As AI advances, its role in predictive maintenance will grow, ensuring your equipment runs ideally and your production stays on track. Real-time data analysis further enhances the accuracy of fault detection and maintenance scheduling, leading to even greater operational efficiencies. Additionally, incorporating traditional techniques such as vibration analysis and thermal imaging can complement AI systems for more comprehensive monitoring. Leveraging sensor technology can also improve data collection, providing more detailed insights for predictive algorithms. Moreover, AI’s trustworthiness continues to improve, making predictive maintenance more reliable and trustworthy over time. The integration of big data analytics from various sources can further refine predictive models, leading to more precise maintenance forecasts.

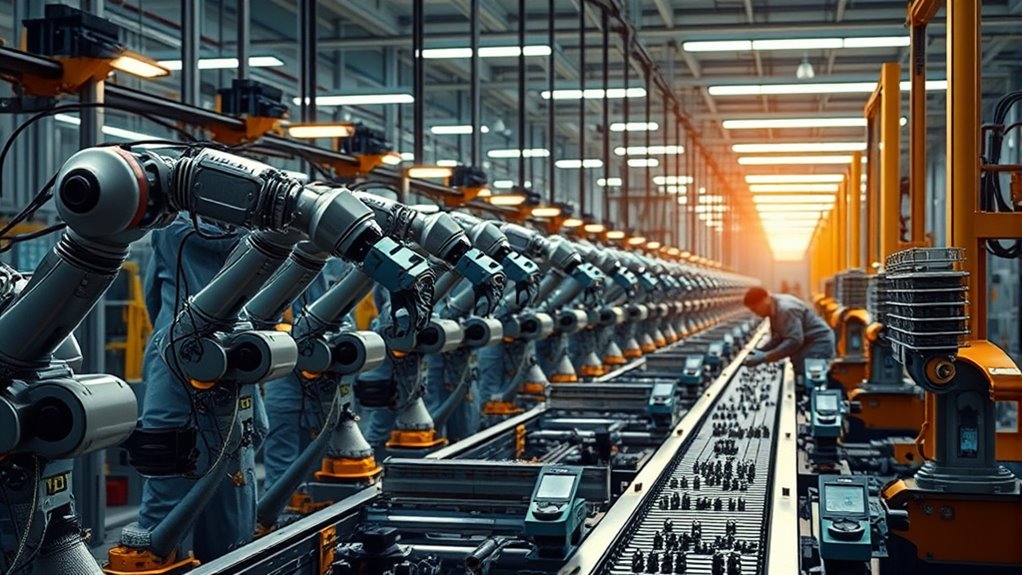

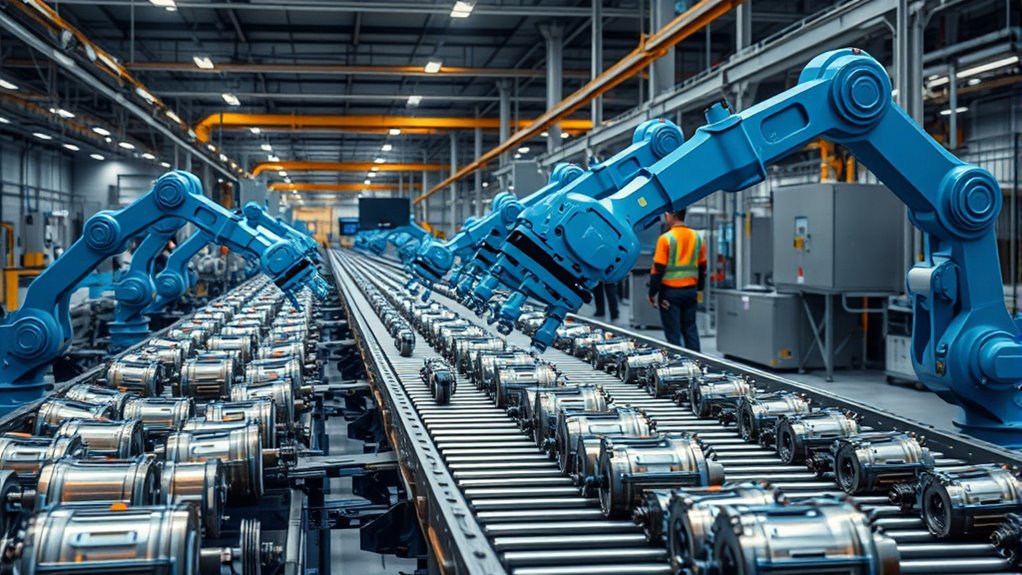

Robotic Assembly Lines

Robotic assembly lines are transforming manufacturing by taking over routine tasks, increasing efficiency, and reducing human error. Today, over 4 million robots operate globally, with China leading at 51% of installations. These robots automate complex processes like welding, painting, and material handling, thanks to advanced AI and machine learning that boost their precision, speed, and adaptability. In sectors such as automotive and electronics, robots perform repetitive, high-volume tasks, ensuring consistency and quality. AI-powered vision systems enable defect detection and precise object recognition, while collaborative robots (cobots) foster flexible, human-robot workspaces. As automation continues to grow—projected to reach over $264 billion by 2026—factories become safer, more productive, and better equipped to meet rising demand for electric and autonomous vehicles. Vision systems analyze past tasks for pattern recognition and optimization, enabling continuous improvement and more efficient workflows in manufacturing environments. Additionally, the integration of industrial AI systems enhances predictive maintenance, reducing downtime and further increasing overall efficiency. This integration is driven by AI content clusters, which facilitate targeted improvements across various manufacturing processes. Furthermore, understanding Relationships – Personality Test can help optimize team dynamics within automated workspaces, leading to smoother operations and better human-machine collaboration.

Predictive Maintenance: Reducing Downtime With Intelligent Machines

Predictive maintenance is transforming industrial operations by using advanced technologies to anticipate equipment failures before they happen. This approach minimizes downtime and cuts maintenance costs considerably. Thanks to AI, IoT, and data analytics, you can monitor equipment in real-time, enabling proactive decisions. The market for predictive maintenance is rapidly growing, with a 25% annual increase, highlighting its importance across industries. By adopting predictive maintenance, you can enjoy benefits like extended equipment lifespan, improved operational efficiency, and enhanced safety standards. It also helps avoid costly emergency repairs and reduces unexpected outages. Sensors and connected devices are employed by 48% of plants for data capture; 30% are exploring such solutions. However, successful implementation depends on high-quality data, seamless system integration, and skilled personnel to interpret insights effectively. Embracing these technologies puts you ahead in optimizing production and maintaining competitive edge.

Skill Sets Needed for the AI-Driven Manufacturing Environment

To thrive in an AI-driven manufacturing environment, you’ll need strong technical troubleshooting skills to quickly resolve system issues. Maintaining AI systems requires a solid understanding of system upkeep and regular updates to guarantee peak performance. Additionally, proficiency in data analysis helps you interpret insights and make informed decisions that improve workflows.

Technical Troubleshooting Skills

Have you ever wondered what skills are essential for troubleshooting in an AI-driven manufacturing environment? You need to be comfortable working with AI-powered tools that analyze data quickly, helping you identify issues faster. Understanding predictive maintenance is key—recognizing patterns to prevent breakdowns before they happen. Being able to interpret AI-generated reports allows you to make informed decisions on the spot. You also need autonomy in resolving problems, trusting AI suggestions while maintaining control. Plus, staying updated on new AI solutions ensures you keep pace with technological advances.

- Using AI tools for data analysis and problem detection

- Recognizing patterns in predictive maintenance alerts

- Interpreting reports and metrics accurately

- Applying AI recommendations confidently

- Troubleshooting with minimal downtime

AI System Maintenance

Maintaining AI systems on the factory floor requires a blend of technical skills and practical knowledge. You need to understand predictive maintenance, using sensor data to foresee equipment failures and schedule proactive repairs. Familiarity with calibration and testing ensures AI systems remain accurate and reliable. Knowing how to integrate AI with existing machinery and software is essential for seamless operations. Cybersecurity measures are a must to protect these systems from threats. You should also have mechanical knowledge to troubleshoot hardware issues and digital literacy to navigate complex software interfaces. Adaptability helps you stay current with evolving technologies, while collaboration skills enable effective teamwork with AI and human colleagues. Continuous learning keeps your skills sharp, ensuring smooth AI system performance and longevity.

Data Analysis Proficiency

Mastering data analysis is essential for leveraging AI effectively on the factory floor. Your ability to interpret and visualize manufacturing data directly impacts process improvements. With strong skills in predictive analytics, you can forecast equipment failures and demand shifts, minimizing downtime. Data wrangling ensures clean, accurate data from sensors and systems, supporting reliable insights. Understanding AI and machine learning concepts enables you to develop models that make sense of complex data and support decision-making. Additionally, tracking operational metrics like OEE, cycle time, and defect rates helps you identify inefficiencies and drive continuous improvement.

- Interpret and visualize manufacturing data for insights

- Use predictive analytics to forecast failures and demand

- Clean and preprocess data from multiple sources

- Understand and support AI/ML model development

- Track KPIs for operational excellence

Enhancing Safety and Efficiency Through Smart Automation

Smart automation powered by AI is transforming factory safety and efficiency by enabling real-time monitoring, predictive maintenance, and intelligent task management. You benefit from AI-driven safety systems that analyze live data to detect hazards and unsafe behaviors, reducing accidents. IoT sensors continuously monitor environmental and equipment conditions, alerting you to potential issues before they escalate. Predictive analytics foresee maintenance needs and risk scenarios, allowing preemptive actions. Here’s a visual overview:

| Safety Monitoring | Workforce Support |

|---|---|

| Real-time hazard detection | Cobots handle dangerous tasks |

| Environmental sensors | Enhanced safety features |

| Predictive maintenance | Safer, more efficient operations |

This integration guarantees compliance, minimizes risks, and boosts productivity across your factory.

The Impact of AI on Job Security and Workforce Dynamics

As AI continues to advance, it markedly reshapes your job security and the dynamics of the workforce. You might face displacement, with 14% of workers affected by automation, and rising unemployment among recent grads. Job polarization intensifies, putting low-skilled roles at higher risk, while even educated workers aren’t immune. The workforce is evolving, with new roles emerging that demand advanced technical skills. You’ll see increased collaboration between humans and AI, making adaptability essential.

- Job displacement impacts a broad range of industries, not just blue-collar roles

- Growing demand for digital and analytical skills across all levels

- Income inequality may widen due to skill gaps

- Vulnerable groups, like Black workers, face higher displacement risks

- Continuous learning becomes key to job stability

Training and Upskilling for the Future of Industrial Work

In today’s rapidly evolving industrial landscape, continuous training and upskilling are essential for staying competitive. Over half of workers have already engaged in some form of skill development, reflecting a growing recognition of its importance. Employers prioritize soft skills like analytical thinking, resilience, and adaptability, alongside technical skills such as AI, big data, cybersecurity, and networking. As automation and AI reshape factory tasks, manual dexterity and endurance are declining in demand. However, fewer than 25% of workers feel they have the skills needed for career growth, and less than 4% of employers actively support upskilling initiatives. Most workers rely on external sources like educational institutions, highlighting a gap in employer-driven programs. Investing in structured training is crucial for workforce resilience, innovation, and long-term competitiveness.

Embracing Innovation: Strategies for Integrating AI Into Manufacturing Careers

Integrating AI into manufacturing careers requires a proactive approach to innovation and strategic planning. To succeed, you need to understand industry trends and invest in the right technologies. Start small with pilot projects and scale up as you see results. Focus on areas where AI can boost efficiency, like predictive maintenance and quality control, to maximize ROI. Embrace a culture of continuous learning, encouraging workers to upskill and adapt. Address workforce concerns by planning retraining initiatives and clear communication. Remember, AI can create new roles and enhance existing ones if integrated thoughtfully.

Integrating AI in manufacturing boosts efficiency, fosters innovation, and creates new roles through strategic planning and continuous learning.

- Invest in pilot projects to test AI applications

- Prioritize automation that improves quality and reduces errors

- Develop retraining programs for displaced workers

- Foster a culture of innovation and adaptability

- Monitor industry trends for future opportunities

Frequently Asked Questions

How Does AI Impact Blue-Collar Worker Compensation in Manufacturing?

You might wonder how AI impacts your compensation in manufacturing. It can boost productivity, leading to higher wages for workers who adapt and contribute to efficiency. However, automation can also shift profits to owners, possibly widening income gaps. AI may introduce new pay models rewarding human skills and improve claim processing, benefiting workers. Still, the overall effect depends on how companies and governments manage these changes to guarantee fair rewards for your efforts.

What Ethical Considerations Arise From AI Replacing Human Jobs?

Imagine a delicate balance beam stretched across a chasm—AI’s rise challenges your sense of fairness and human dignity. You must consider ethical issues like job loss, income inequality, and exploitation. As you navigate this landscape, prioritize fair labor practices, transparency, and worker retraining. By doing so, you safeguard human rights, ensuring that technology uplifts rather than diminishes the value of human effort and societal well-being.

How Can Small Manufacturers Adopt AI Without Extensive Resources?

To adopt AI without extensive resources, you should start small with modular, cloud-based solutions that are cost-effective and scalable. Partner with tech firms for expertise and implement collaborative robots to complement your workforce. Focus on incremental projects like predictive maintenance or quality control to build confidence. By gradually integrating AI, you can enhance efficiency, reduce costs, and stay competitive without overextending your budget or requiring deep technical skills.

What Are the Long-Term Career Prospects for Blue-Collar Workers in Ai-Driven Factories?

Your long-term career prospects depend on your ability to adapt, learn, and grow. You’ll find new opportunities in AI maintenance, operation, and data analysis, while traditional roles evolve. By reskilling and embracing technological change, you can stay relevant. Training programs, apprenticeships, and personalized learning help you develop new skills. Staying proactive and open to continuous learning guarantees you can thrive in an AI-driven factory environment.

How Do Companies Measure the Success of AI Integration on the Factory Floor?

You measure AI integration success by tracking operational efficiency, like throughput, downtime reduction, cycle time improvements, and overall equipment effectiveness. You also look at labor impact metrics such as labor savings, productivity, safety, and employee satisfaction. Financial outcomes like ROI, cost per unit, and revenue growth are key, along with AI system performance indicators like accuracy, latency, and scalability. These metrics help you determine if AI delivers better productivity, quality, and cost savings on the factory floor.

Conclusion

As you stand on the factory floor, imagine the hum of intelligent machines seamlessly working alongside you, each task flowing smoothly like a well-oiled dance. Embracing AI means stepping into a future where safety, efficiency, and innovation intertwine, transforming your role into one of skill and insight. Together with smart technology, you’ll navigate this evolving landscape, turning challenges into opportunities and building a resilient, thriving workforce united by progress.